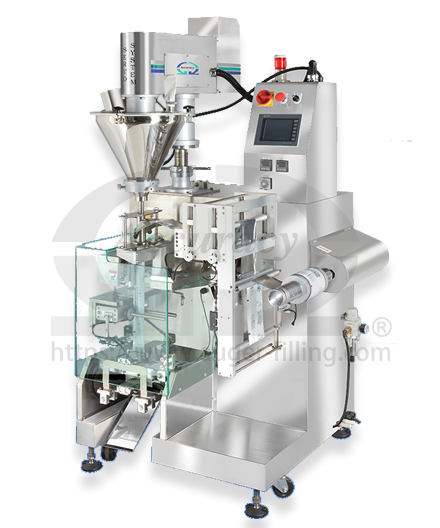

Packaging equipment and machines are instruments that enable you to package items on a massive scale using automated techniques. They can include vacuum packaging machines, filling machines, sealing machines, labeling machines, box forming machines, etc. These machines can be utilized to boost efficiency and speed, reduce labor costs, improve packaging quality, and cut costs. They can be costly to buy and maintain. Additionally, they require some technical know-how to work properly.

These Are The Fundamental Tenets Of Equipment For Packaging:

Protection- Packaging equipment should protect the product from damage, contamination, and deterioration during storage, transportation, and distribution.Containment- Packaging equipment should contain the product in a secure and stable manner, preventing spillage, leakage, and waste.

Convenience. The packaging equipment should be user-friendly, making it simple to use and also make it easily accessible.

Efficient packaging- Equipment should be designed to maximize the production process which will reduce waste and boost the speed of production.

Cost-effectiveness. Packaging equipment should have an equilibrium between price and performance. This will provide value to the end user and is also economically feasible.

The equipment used for packaging should be easy to use. It should be simple to maintain and clean.

Sustainability- The packaging equipment will reduce the amount of material used and waste, become environmentally sustainable, and increase environmental impact.

Packaging equipment can be designed to offer the highest quality performance, protection and convenience for the end-user and manufacturer. Have a look at the top rated Craft breweries for more info.

How Does Vacuum Packaging, Box Making Filling, Cooling Sealing And Cooling, Marking And Labeling Function?

Vacuum packaging equipment. These machines remove air from the bag and seal it to extend the shelf lifespan. These machines utilize the vacuum machine and the heat sealer to seal bags or containers containing a product. They can be programmed to dispense the desired amount of product. They are often used for liquids or pastes as well as powders.

Sealing equipment They are suitable for items like medical equipment, food items or electronic equipment.

Labeling equipment- These devices attach labels to the packaging or to the products. The label can be attached with either pressure-sensitive, heat-sensitive, or glue.

Box forming machines- These machines form boxes or cartons from thin pieces of paperboard. The machine folds and glues paperboard into the shape you want. This box is now ready to be shipped and packed.

These equipment and machines use different technologies to accomplish their tasks, including sensors control, a variety of mechanical systems. It is also possible to integrate them in a bigger line of packaging to boost speed and efficiency. Take a look at the best Adapting sustainable green packaging for site recommendations.

Automated flexible cooling solutions that can be scaled provide an efficient and automated temperature control for variety of industrial processes. They typically employ sophisticated technologies, such as thermocontrol systems, heat exchangers, and refrigeration units to make sure that temperatures are controlled precisely and products are assured of safety and consistency. Automated, scalable cooling solutions are customizable to meet customer needs and can easily be reduced or increased when production demands change. They can also be easily integrated with other manufacturing equipment to boost efficiency. Automation scalable cooling solutions offer numerous advantages, including improved product quality and reduced time to repair. Have a look at the best increase production rate for site recommendations.

What Are The Most Important Factors To Consider When Buying Packaging Equipment?

Packaging requirements- The type of packaging equipment chosen will be based on the desired production volume.

Integration Integrating packaging equipment into existing production lines must be taken into consideration, including compatibility and ease-of-integration.

Maintenance and Support: the availability of support and maintenance along with the expense and ease of maintaining equipment should be evaluated.

Cost- You should consider the cost of the equipment, as well as associated expenses like installation, training, maintenance and other costs in your overall budget.

Energy efficiency- Efficiency of energy and associated costs must be taken into consideration, since energy consumption has a significant impact on operating costs.

It should be user-friendly.

Conformity to industry standards. It is crucial to be in compliance with applicable standards of the industry (e.g. the food safety rules) to ensure that the equipment is appropriate for its intended use.

These elements are essential to ensure that you make the right choice when buying packaging equipment. Read the most popular Enoline Solutions for website examples.

What Do You Need To Know About Product Safety And Heat Sealing?

Packaging using heat sealable materials like plastic is heat sealing. Heat sealing involves the use of heat and pressure to join materials, creating an impenetrable seal.

Seals that are reliable A good seal is essential to shield the item from spoilage as well as leakage.

Automated packaging techniques Automated packaging is a standard method of heat sealing that improves efficiency while maintaining consistency.

Robotics, programmable logic controllers, and robotics Robotics, along with logic controllers that can be programmed (PLCs) are employed in automated packaging as well as heat sealing. These controllers control the process in order to guarantee consistency and high-quality results.

Preventative maintenance program In order to guarantee durability and reliability of the equipment it is essential that packaging equipment is maintained regularly.

Use of film to reduce costs for packaging materials Quality and cost of heat sealing films could be a significant influence on packaging material costs. The choice of the right type of film will help to reduce production waste, increase the performance of your product, and boost the speed of production.

Reducing package price- To reduce the cost of packaging, it's important to improve the process of packaging, including the heat sealing process, to minimize waste and improve efficiency.

Packaging processes- Heat seal is just one of the steps of a bigger packaging process that includes the filling, labeling, packing, and shipping. It is essential to know the entire process and how heat sealing can be integrated into it, to ensure a cost-efficient and successful packing operation. Have a look at the top rated Integration for site tips.